In the intricate world of modern electronics, the foundation of nearly every advanced device lies in a seemingly simple disc: the semiconductor wafer. These highly engineered substrates are the starting point for integrated circuits, microprocessors, and a vast array of electronic components that power our digital lives. However, merely possessing these critical materials isn’t enough; their effective utilization is paramount to achieving optimal performance, yield, and cost-efficiency in manufacturing. This guest post will delve into expert tips for maximizing the potential of semiconductor wafers, from selection to processing, ensuring your projects reach their full potential.

The Foundation: Understanding Your Semiconductor Wafers

Before any processing begins, a deep understanding of the specific semiconductor wafers you are working with is crucial. Not all wafers are created equal, and their characteristics directly impact subsequent fabrication steps and final device performance.

Material Selection and Specifications

The choice of material – typically silicon, but increasingly GaAs, SiC, and GaN for specialized applications – dictates many fundamental properties. Silicon, for instance, is prevalent due to its abundance, well-understood processing, and excellent electrical characteristics. However, for high-power or high-frequency applications, materials like silicon carbide (SiC) and gallium nitride (GaN) offer superior bandgap, thermal conductivity, and electron mobility, despite being more challenging and costly to process.

Key Consideration: Always match the wafer material and its specifications (resistivity, crystal orientation, doping type, thickness, flatness, surface roughness) to your device requirements. A mismatch here can lead to significant yield losses or performance bottlenecks down the line. For example, a low-resistivity wafer is essential for power devices to minimize ohmic losses, while high-resistivity semiconductor wafers are preferred for RF applications to reduce parasitic capacitance.

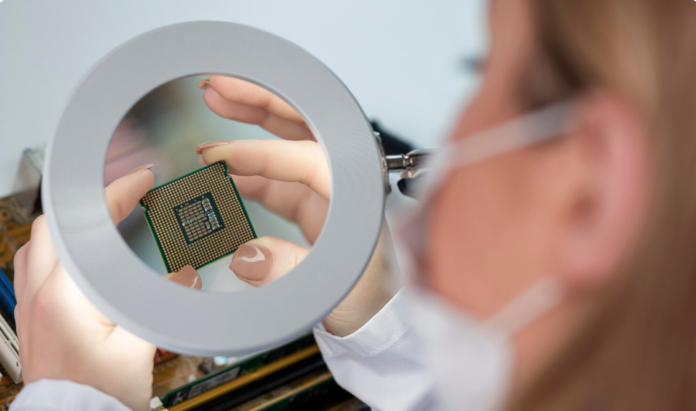

Inspection and Quality Control

Even from reputable suppliers, thorough incoming inspection of semiconductor wafers is non-negotiable. Defects such as particles, scratches, crystal dislocations, or variations in flatness can propagate through the entire fabrication process, leading to non-functional devices.

Actionable Tip: Implement robust incoming quality control procedures, including visual inspection under high magnification, surface particle counting, and flatness measurements (e.g., using interferometry). Early detection of defects can save immense costs associated with processing faulty material. Industry data suggests that a defect caught at the wafer stage can cost 10x less to rectify than one discovered after packaging.

Optimizing Processing: From Cleanroom to Etch

The journey of semiconductor wafers through a fabrication facility is a delicate dance of precise steps, each requiring meticulous control.

Maintaining a Pristine Environment

The cleanroom environment is the lifeblood of semiconductor manufacturing. Airborne particles, even microscopic ones, can act as killer defects on the wafer surface, shorting out devices or causing open circuits.

Expert Insight: Adhere strictly to cleanroom protocols (e.g., ISO Class 1 to Class 7 depending on the process step). Regular air quality monitoring, proper gowning procedures, and minimizing human interaction with exposed wafers are paramount. Even a single 0.1µm particle can ruin a state-of-the-art transistor.

Precision in Thin Film Deposition

Whether it’s epitaxy, PVD, CVD, or ALD, thin film deposition is a critical step in building up the device layers. Uniformity, adhesion, and stress control are vital for device reliability and performance.

Practical Advice: Calibrate and maintain deposition equipment regularly. Monitor film thickness and uniformity across the wafer using in-situ or ex-situ metrology tools (e.g., ellipsometry, spectrophotometry). Poor uniformity can lead to variations in device characteristics across the wafer, reducing overall yield.

Mastering Photolithography and Etching

Photolithography defines the patterns, and etching transfers those patterns into the underlying films. These are arguably the most critical and complex steps, directly impacting device dimensions and features.

Key Strategy: Optimize resist selection, exposure parameters, and development processes for maximum resolution and critical dimension (CD) control. For etching, select chemistries and plasma parameters that offer high selectivity to the desired material over the mask and underlying layers, while minimizing damage to the wafer surface. Anisotropic etching, for instance, is crucial for creating vertical device structures on semiconductor wafers.

Post-Processing and Analysis: Ensuring Device Reliability

Even after the primary fabrication steps, the effective use of semiconductor wafers extends into post-processing and rigorous analysis.

Dicing and Packaging Considerations

Once devices are fabricated on the wafer, they need to be separated into individual chips (dicing) and packaged. The dicing process itself can introduce stress or micro-cracks if not executed properly.

Actionable Tip: Optimize dicing parameters (blade speed, coolant flow, laser power) to minimize chipping and stress. Consider the kerf width to maximize the number of dies per wafer. Proper die attach and wire bonding techniques are also crucial for maintaining electrical and mechanical integrity.

Comprehensive Characterization and Failure Analysis

Thorough electrical testing and physical characterization are essential to validate device performance and identify any anomalies. When failures occur, detailed failure analysis is critical for process improvement.

Expert Recommendation: Implement a robust in-line and end-of-line testing strategy. Utilize techniques like SEM, TEM, EDX, and FIB for physical failure analysis. Understanding the root cause of failures in even a small percentage of devices can lead to significant improvements in yield and reliability across future batches of semiconductor wafers.

Conclusion

The effective utilization of semiconductor wafers is a multifaceted discipline, demanding expertise at every stage from initial material selection to final device characterization. By meticulously understanding wafer specifications, maintaining a pristine processing environment, optimizing fabrication steps, and implementing rigorous quality control, manufacturers can unlock the full potential of these foundational materials. The continuous pursuit of precision, cleanliness, and analytical rigor will not only enhance device performance and reliability but also drive innovation in the ever-evolving landscape of microelectronics. Mastering these expert tips will undoubtedly pave the way for ground breaking advancements built upon the humble, yet powerful, semiconductor wafer.

Author Bio:

The author is a seasoned expert in materials science and semiconductor manufacturing, with over a decade of experience in process optimization and advanced materials characterization. Their work focuses on enhancing the performance and reliability of electronic components through meticulous attention to detail in fabrication processes. They are passionate about sharing knowledge to empower engineers and researchers in the microelectronics industry to overcome complex challenges and drive technological innovation.”